Services

Testing of cylinder heads

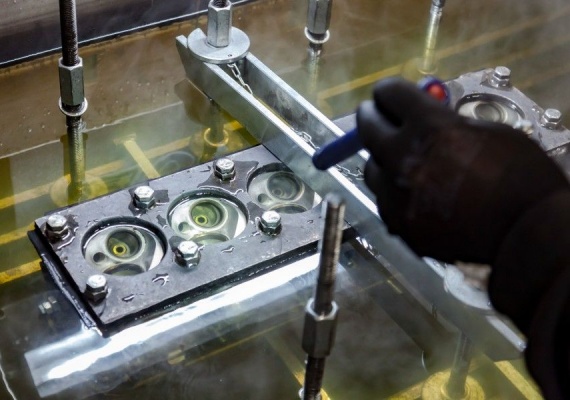

Every cylinder head testing starts with cleaning and machine washing. Cylinder heads needs to be clean to be properly tested. Testing is performed on the PTR 1600XLH machine, which in terms of dimensions allows testing of all types and sizes of cylinder heads. Testing is based on the principle of plugging all water outlets (simulation of head gasket) and then injecting pressurized air into the circuit. The cylinder head is then immersed in a hot-water bath and if it contains any cracks or fissures, a stream of air bubbles will be observed rising to the surface of the bath. During the testing, a cylinder head can also rotate a full 360 degrees.

Apart from the cylinder head testing machine, experience is also important. Through many years of experience and the significant number of cylinder heads tested, we already know which cylinder head models are more prone to cracking and where to pay special attention. By combining machine washing, testing equipment and experience, we can determine with great certainty the impermeability of the cylinder head.

In addition, we offer the Magnaflux magnetic particle testing, although mainly for testing surface cracks, for example on crankshafts or engine blocks and on gray cast iron cylinder heads.